How Is Engineered Hardwood Flooring Made?

What Is Engineered Hardwood Flooring?

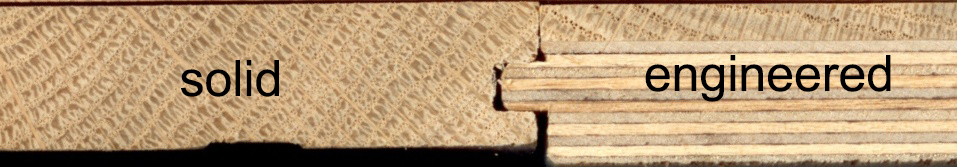

Engineered hardwood is a flooring material made from numerous layers of wood, as opposed to coming from one single plank like solid hardwood does. The crisscross layer structure provides extra dimensional stability so that each plank is less prone to weather-based expansion or contraction. The wood species used to make the decorative top layer gives the flooring its name: a top layer of acacia will make an engineered acacia floor, whereas a maple top layer will make an engineered maple floor and so on. A common misconception holds that engineered hardwood is somehow less ‘genuine’ than solid hardwood. This is highly inaccurate! Both solid and engineered hardwood floors are made of real wood – the only difference is the structural constitution.

A cross-section of the two hardwood types.

How Is It Made?

The layers composing an engineered hardwood plank are bonded together with adhesive and pressure. The number of layers varies; a 3-ply engineered floor will have three layers, a 5-ply engineered floor will have five layers, etcetera.

While all engineered hardwood follows the same layered concept, there are two separate ways to achieve the final finished look:

• Rotary Cut Veneer. The top hardwood layer is removed from a section of wood using large lathes. Since this peels rather than cuts, it lets more dramatic grain patterns show off their beauty.

• Quarter Sawn Veneer. The log is cut into quarters prior to being cut. Since the growth rings are not visible when this method is used, it produces a lovely straight grain pattern.

• Slice Cut Veneer. A piece of slice cut veneer is cut from a plank just like a piece of solid hardwood. It highlights finer graining and allows for a thicker wear layer.

What Types Are Available?

Engineered hardwood is available in as many different species as solid hardwood! Both domestic and exotic woods are popular choices and make beautiful floors. There’s also a range of quality grades available at different price points so you can easily factor cost into your decision-making process. Cabin Grade hardwoods are a great choice for anyone looking for a more rustic characterful look at a low discount price.

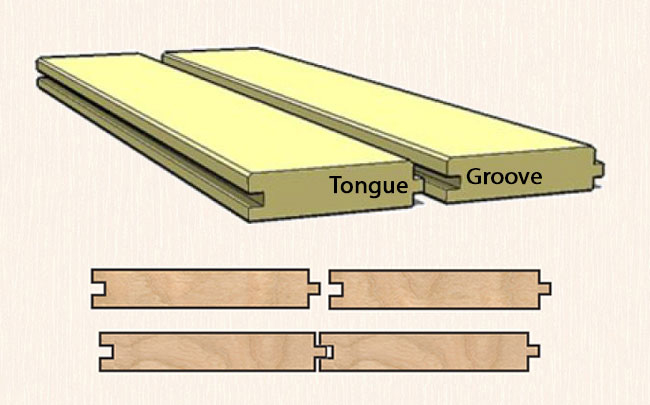

As far as installation options, engineered hardwood can feature the traditional tongue & groove design found on solid hardwood.

While solid hardwood needs to be nailed or stapled, engineered tongue & groove floors can be installed in one of four ways:

• Nailing

• Stapling

• Gluing down directly to the subfloor

• Floating without adhesive

Some engineered hardwoods click together, making installation easier for both professionals and DIY-ers.

How Do I Know If Engineered Hardwood Is Right For Me?

Engineered hardwood is a great choice for anyone who wants the classic wood floor look without having to pay top dollar for solid hardwood. It’s durable, easy to clean, and never goes out of fashion. Of course, just like with any other material, it’s important to factor in your lifestyle, your budget, and where the floor will be installed. It’s critical to look at your subfloor and your room’s moisture content. Check out this post on choosing the right hardwood floor on in our Resource Center.

Follow Team Floors To Your Home on Facebook

Brown Tone

Brown Tone

Unfinished

Unfinished

Red Tone

Red Tone

Golden Tone

Golden Tone

Gray Tone

Gray Tone

Light Tone

Light Tone

Medium Tone

Medium Tone

Dark Tone

Dark Tone

Brown Tone

Brown Tone

Red Tone

Red Tone

Golden Tone

Golden Tone

Gray Tone

Gray Tone

Light Tone

Light Tone

Medium Tone

Medium Tone

Dark Tone

Dark Tone

Brown Tone

Brown Tone

Red Tone

Red Tone

Golden Tone

Golden Tone

Gray Tone

Gray Tone

Light Tone

Light Tone

Medium Tone

Medium Tone

Dark Tone

Dark Tone

Multi Color

Multi Color