Laminate Flooring Glossary

Laminate Flooring Glossary of Terms: A & B

AC Ratings - This is an almost universally used surface durability rating. It’s based on a set of 10 tests performed by a third party organization called the Association of European Producers of Laminate Flooring. Ratings go from 1 to 5, and the rating is the lowest number met in each and evry test. If a certain laminate passes nine tests at the level AC4, and one at level AC2, then it’s an AC2 rated floor. Our article Explaining AC Ratings goes over this rating in detail.

Acclimation - This is when you place your flooring in the room where it will be installed for a few days (your specific instructions will say how long) so the material can become accustomed to the exact conditions of the room, primarily the temperature and humidity.

Acoustical Properties - It means the same thing it does in general, referring to sound characteristics. These stats will usually convey whether sound bounces off your floor or is muffled by it, and whether when walked on it sounds hollow, squishy (‘squishy’?)… or quiet.

Adhesion - The process of sticking two things together. This can refer to other things besides flooring.

Adhesive - Something that does the above, usually a liquid, though tape counts too (what Buzz Lightyear calls “unidirectional bonding strip"). It is now very rarely used with laminate floors.

Aluminum Oxide - This is the most common top coating layer for laminates, and that is a good thing. It’s why laminates can handle wear that hardwood can’t. As a substance it is used as a substitute for industrial diamond in abrasives. It is non-flammable, insoluble in water and an electrical insulator. In 1988 aluminum oxide was removed from the EPA’s lists of potentially dangerous chemicals, and now is even used in hip replacements.

Angle to Angle - A style of installation in which the end joints are locked in first, then the long side is locked in, such that both sides are locked once the plank itself has been installed. That is the most obvious way that it differs from Drop & Lock installations. Four very helpful videos are below under Click Together.

Antistatic - Such a floor will limit the build-up of static electricity.

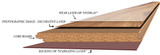

Backer - This is the bottom layer of a laminate floor, or the ‘back’ if the part you look at its top as the ‘front’. It is tightly bonded to the core of the laminate, which is the central, thickest part of it. This layer is resin-impregnated to give the whole plank both strength and flexibility, and to prevent moisture from rising up into the floor. This also prevents the plank from bowing, or ‘dishing’ as it’s sometimes called.

Balanced Construction - This is when the main structure of a thing, with laminate planks that’s the ‘core board’, has similar materials bonded to each side. This is done so the laminate planks will lay flat rather than tending to bow in either direction.

Base Boards – Since walls do not always perfectly meet floors, base boards are very common trimming pieces, resting directly on the subfloor, not over the laminate, and fasten to the walls. These are noted by being much taller than they are wide. They really border a room more than just trim it. Their connection with a laminate is that if this is in place, then your expansion gap must be between this piece and the edge of your laminate floor. That gap would then be hidden by another trim piece connected to the base board, under which the laminate may move, usually a quarter round or a base shoe.

Base Shoe - This is one of the trims commonly used in a laminate floor installation. It’s a partner to the base board. The base board is installed all the way down to the subfloor, and your laminate is installed with a gap between it and the base board. This expansion gap is covered by the Base Shoe, which is attached to the base board and hovers over the gap and the edge of the laminate. In the picture above I show a quarter round in place of a base shoe. They are close to the same thing, but base shoes are taller than they are wide.

Beveled Edge (also called ‘eased’ or ‘chamfered’) - This is the opposite of 'square edged' planks. Here, the edges, sometimes two, sometimes all four, are cut with a slight angle so that where the planks meet each other there will be a small V shaped notch. This outlines the planks, and can add a more natural look to the flooring.

Bond - To join or stick things together. This is usually done with chemicals, pressure or heat. The word can also be a reference to that ‘sticking’, as in, “The bond is quite strong."

Board - You may hear this because it's such a generic term for rectangles used in construction, but in the flooring industry we try to only use this to refer to planks that are made out of single pieces of wood. Solid Hardwood planks would be boards, but planks of laminate flooring should usually just be called 'planks'. Please forgive your customer service person if they fall into the colloquial use of board. Some habits break hard.

Laminate Flooring Glossary of Terms: C

CARB (the California Air Regulatory Board) – Concern for formaldehyde emissions led to an American rating system issued in 2007 by CARB, and often referred to as CARB, or as levels of CARB compliance. The requirements are that formaldehyde emissions from various materials fall at or below a certain number of parts per million air molecules (PPM).| Hardwood plywood (HWPW): 0.05 | Medium density fibreboard (MDF): 0.11 |

| Particleboard (PB): 0.09 | MDF less than or equal to 8 mm. thick: 0.13 |

Adhesives: 0.05

The adhesive levels are lower than the OSHA standards, lower than Europe’s standards (including E0 – see below), and even lower than most of the fish we eat.

Most laminate flooring contains so little in the way of contaminants that they are tend to be listed as contaminant free. If you see older materials, the markings may indicate which part of the initial phases of the law are met by that product. If they say they are Phase 1 compliant, then the adhesive formaldehyde emissions would have to measure equal to or under 0.08 ppm (parts per million), the standard in effect as of January 1, 2009. Phase 2, set as the standard a year later, represents the current standards.

Chatter Marks - These appear as a subtle rippling across the surface of real hardwood caused during the sanding of the board. These can usually only be seen in reflected light on the surface. They are also rarely found on a laminate plank, since these are not sanded.

Chemical Resistance - With flooring this refers to how well the surface can handle cleaning chemicals without degrading, either structurally or visually.| Cigarette Burn Resistance – This describes how a laminate floor resists cigarette burns on its surface. Due to the high temperature resistance of a pore-free aluminum oxide surface coating there should be no visible damage from fallen cigarette ash and even the putting out of cigarette butts. There are better uses of a laminate floor than for putting out cigarettes, just as there are better uses of lungs than smoking them, but should it pop up (or drop down) a laminate floor making this claim should handle it. We even made a video on this. |

Class (specifically ‘Utility Class’ or ‘Load Class’) - This is less universal than AC Ratings, but also measures a floor’s durability. There are seven numbers in two groups. 21-23 are for residential uses and 31-34 are for commercial, with higher numbers reflecting greater durabilities. This article on durability ratings explains both systems in detail.

Click-Laminate - Click Laminate is just a broad term for any laminate floor that uses a glue-free connection. Angle to Angle and Drop & Lock are currently the main kinds available, though Tap N Go is still around. The ends of the boards are cut into special shapes, usually tongues and grooves, which fit together snugly and hold the planks together without need for an adhesive. Here are some videos on the various styles:Coating - This is the broad category of any chemical deliberately put onto the top layer of a floor to protect it. It can include anything from the aluminum oxide layer which is basically part of most laminate floors to any of the painted on finishes for hardwood to one’s ‘waxing’ a floor as regular maintenance (which we do not do with laminates, by the way, not ever).

Colorfastness (also called ‘light resistance’) - This describes a material’s ability to retain its original color levels after exposure to light. In flooring the term comes up most frequently when discussing carpet, as it was first popularized to describe dyes in yarns and fabric. With laminated, this feature is usually described as ‘fade resistance’.

Compact Laminate - This term is generic about the laminate construction process, beyond just flooring. In fact it doesn’t even come up much with floors, but since you may hear it we will explain. This refers to any laminated product, including commercial counter tops, furniture, wall surfaces – anything, which is made using the High Pressure Laminate method. It results in a laminated product 2mm thick or more. There are plenty of laminate floors produced with the HPL method, and I can’t think of a laminate floor under 2mm thick, so the word may just be out of use in our industry (mostly, of course) because it describes all of them. Like saying they’re in a solid, not gaseous form.

Continuous Press Laminate (CPL) - This is another generic lamination term not usually associated with flooring. It’s a process of producing laminated paper one might use on another surface. The benefit of the method is that the resulting paper comes in a roll, able to be cut to length for a customer. Often a glue is involved in this process, and most, if not all, of our laminate floors are made with pressure and heat, no adhesives.

Core - This is what you might think of as ‘the board’ part of a complete laminate plank. It’s the main structure of a laminate plank to which a backing is attached for the bottom and an image with a protective coating for the top. Whether made of high or medium density fiberboard, the fibers are usually recycled wood, and occasionally resins, not plastic, a word often associated with laminates for reasons we cannot fathom here.

Covering - This means exactly what it says, but you may hear your laminate called a ‘floor covering’ especially by those who speak technically about flooring such as installers, manufacturers and some sales people. It sounds like that should refer to an area rug or a big sheet of plastic you use when painting the ceiling, not the laminate flooring itself. That’s just your floor, right? Yes, it’s certainly not wrong to call it that. This term comes in because technically the laminate is not what’s keeping you from falling through to the next level of your house. Your joists do, the subfloor does, and if you lived in a Little House on the Prairie in the 1800’s your hardwood might have done this as well, going in perpendicular to the joists and actually keeping you and your bed in place. Since laminates are not structurally essential, they can be called a ‘floor covering’.

Crook

- This word applies more to hardwood, but those often crossover. It’s a word that describes a plank that has a bow rather than lying flat. You might think of the plank as warped, but it isn’t, as this video covers. Locked into place these planks settle. It is an issue with hardwood because you can have much shorter planks, even 12" pieces, where such a curve can make installation difficult.

Crowning - When there is no (longer) room for a laminate floor to expand into expansion gaps, the planks will push against each other and individual planks will raise up in the middle, forming a curve, like a hill. Crowning results from expansion being cramped, cupping from excess humidity or moisture.

Cupping - This is the opposite of crowning. Because of excess moisture the edges of the planks rise in relation to their centers, forming ‘cups’. Water would gather there if poured. Cupping results from moisture and humidity. Crowning happens due to expansion cramping. [use image Laminate Cupping in LP images]

Cure - It’s a term of chemistry in manufacturing, when a substance is subjected to a chemical process in order to prepare, preserve, harden, strengthen or finish it. With laminate floors it can refer to the use of heat, pressure or both to strengthen the final laminate material.

Laminate Flooring Glossary of Terms: D

Décor Layer - This is the combined top layer of a laminate floor. It's the picture or pattern you chose because you liked its look as covered by a transparent, protective layer, so to your eyes it is “the top” but technically it's two layers.

Décor Paper - For laminate floors this is the image part of a floor. Usually it’s a very sharp photograph of a specific style of wood plank, but it can also resemble stone tiling or other styles of flooring. The paper is impregnated with a resin and heated to cure so that the resulting sheet is extremely durable. This strong décor paper plus the protective coating combine to make the Décor Layer above.

Deep Embossed Hand Scraped Texture - This is one of our terms. In hardwood, hand-scraping goes back hundreds of years. Artisans textured the tops of the wood planks individually for decorative purposes. This phrase describes laminate floors that have deliberate, pleasant grooves in the surface to replicate the look and feel of a well sanded and polished hand-scraped hardwood floor.

Deflection - This is the term for the bending of any material which is suspended between supports when a weight is placed upon it somewhere in between those supports. For example, if you put out two chairs and rested a board with one end on each seat, then stepped onto the board, if the board bended as you stepped onto it, the bend would be called deflection.

Delamination - This is a defect or type of damage to a laminate floor. It describes what is happening when the décor layer either peels off or loses adhesion from the rest of the floor panel.

Density - A physics term: a substance’s mass per unit of volume in specific conditions of pressure and temperature. You probably won’t see it listed in a lot of laminate floors’ specs because what we really want to know – how tough it is – is expressed through AC ratings, but if it's present you should see it expressed as pounds per cubic foot (lb/ft3) or kilograms per cubic meter (kg/m3)

Depression - It would be similar to a dent, but perhaps without any cracking or breaking of the surface, though technically dents also fall into this category of damage.

Dimensional Stability - This refers to any floor plank’s ability to resist changing shape or size due to temperature and/or humidity. Solid hardwood usually has pretty low dimensional stability because it shrinks and expands quite a bit when those conditions change. On the other hand our loose lay vinyl is designed not to expand or contract at all, so it has a very high dimensional stability. Its dimensions, length and width, are stable. There is quite a range among the different floor types.

Direct coating – This is another term for the more commonly used Direct Pressure Laminate (DPL) explained below.

Direct Laminate Flooring - The technical definition is “A flooring product in which resin impregnated material layers are permanently bonded to a core.” I think we now just call this “Laminate Flooring,” as there don’t seem to be any other kinds of it.

Direct Pressure Laminate (DPL) - It’s one of two main methods of laminate production, the other being High Pressure Laminate (HPL). DPL laminates have 4 layers instead of HPL’s 5, and the layers are bound together in a single step via 300 to 500 pounds per square inch of pressure at about 400 degrees Fahrenheit. Of the two, this is the most common process for laminate production, making floors which fall between AC1 and AC4 or classes 21-32 for their durability ratings. They are also more flexible than HPLs, so there are more styles and colors available with this process.

DPL (Direct Pressure Laminate) – (up one spot)

Disposal – Since laminate floors are made of natural materials, any leftover laminate flooring can be disposed of with your normal household garbage. The bulk of a laminate floor is primarily made from the sawdust and bits of wood used in other construction, you see. Now, a completely removed floor should be taken directly to a waste disposal site because all of that wood is going to rot.

Distressed Look – This is often combined with hand-scraped flooring, and that makes sense on a shopping category page, but the looks are slightly different. Distressed flooring basically looks like it has been whapped with wires. The effect is that of lines and thin grooves on the surface here and there, often in groups. Hand-scraped floors have wider, more fluid grooves and something of a wavy style to the surface. With laminates both are done artificially. The benefits are having the look with the durability benefits of a laminate floor, and having the looks with a smoother surface (so no threat of splinters). For some pictures, you should see this blog piece we wrote: What is Handscraped Hardwood Flooring?

Laminate Flooring Glossary of Terms: E-G

Here are links to the other pages:

E0, E1, E2 and E3 - These are Emission Classification ratings, or classes, established by the European Panel Federation. Concern for formaldehyde emissions led to a number of rating systems. The American rating system, known as CARB and described above, was issued in 2007, following ratings enacted by Europe in 2004 and Japan in 2000. These classes indicate how much formaldehyde is released from wood used in manufacturing. The lower the number, the lower the amount that was emitted in testing.

| Emission Class | Emission Limit (ppm) |

| E0 | Less than or equal to 0.041 |

| E1 | Less than or equal to 0.08 |

| E2 | Less than or equal to 0.16 |

| E3 | Greater than 0.16 |

These European standards and testing methods are delineated on The Engineered Wood Association’s website (EN 13986 is particularly on point)

Eased edge – It’s another term for ‘Beveled’ up above.

Edge Design – The options range from beveled to straight, with some steps in between. Beveled floors have either two or all four sides of a plank cut so that a V shape forms where the planks meet, and straight edged floors are designed for a smooth surface to be continuous from plank to plank

Here's a 'Square Edged' floor.

Here's a 'Square Edged' floor.

Electrostatic charge – It’s what zaps you when you touch things. With non-conductive surfaces, electricity has nowhere to go so it stays (static) in place until you, who are a conductor of electricity, make yourself available and get shocked. The build-up is of an electrostatic charge. This tends to happen with low humidity in a room, which our heaters in winter are very good at giving us. Since laminate flooring is not just a piece of wood, but a combination of materials with, most important, a special surface coating, laminates can bring about this effect. Some producers, Kronotex and Quick-Step for example, have their own, patented methods of rendering that coating anti-static.

Embossing used to texture a floor

Embossing - A process by which the surface of a thing, a floor panel in our case, the panel is given a specific texture. This process gives us laminates with distressed or hand-scrape styled surfaces.

Emission classification – (see E0, E1, E2 and E3 above)

End Joint - This is the place, usually a straight line, where the smaller sides, the ends, of two pieces of flooring have been connected.

Environmentally friendly - What this exactly means changes from year to year, but basically it refers to how little a product’s production, existence and use negatively impacts the natural environment or the place where it will be used – your home, in our case. Sometimes this is just referred to a ‘green’, and laminate flooring is a pretty green product.

Equilibrium Moisture Content - It’s a great term, but one we don’t use very much. This is the point when the humidity in the room is at the exact point where the material does not gains or lose and of its moisture. I suppose we don’t refer to it because it’s not practically maintainable in the home or in most places where our floors will wind up. If we wrote about it, it would be to say “Since our homes almost never remain at the point of Equilibrium Moisture Content…”

European Panel Federation - this is the group that sets Europe’s standards for wood materials used in construction. They are connected with the Emission Classifications described at E0-E3 above and also set standards for other qualities such as strength of the material and other things that concern those in construction.

Exotic Style Laminates - In flooring, specifically hardwood, ‘exotic’ refers to species of wood that are not domestic, not native to North America. They come from South America, China, Europe – anywhere but here (we’re in the US, we Floors To Your Home people). These tend to be rare, expensive and to have qualities domestic floors just don’t. The benefit with a laminate floor is that laminates matching an exotic hardwood are no more expensive than any others. The image makes no difference in cost.

Expansion - The way this term is relevant in flooring has to do with how all natural materials respond to temperature and humidity changes. Anything with wood, and laminate is made from wood, will expand and contract. Not much – we’re talking about maybe a quarter inch over an entire medium sized room, not feet or even inches – but it has to be accommodated.

Expansion Gap - This is how we accommodate expansion. When installing a floor that responds to the environment, rather than laying it all the way to and against the walls, or any other vertical surface, we leave a space. It’s a little space, anywhere from 1/8” to ½” – your directions will give the numbers – left between the edge of the flooring and the wall. A piece of trim hovers over this gap, and over time, very, very slowly, your floor slides under it as it expands and contracts.

Factory Warranty - We have a whole series explaining warranties, what they are, how they work, what to look for and everything we could think of. This detail? A factory warranty is a warranty given by the manufacturer of the floor itself. This differs from a store warranty, for instance, or an installer’s warranty. These designations just specify who is responsible for which things if you have multiple warranties.

Fade Resistant (also called ‘colorfastness’) - It’s what it sounds like, how resistant something is to losing color over time or due to direct sunlight. Most hardwood floors will respond to sunlight, fading or just changing colors. Most laminates do not at all. The aluminum oxide surface coating and developments in the photo paper are designed to prevent it.

Fiberboard - This is the broad term describing the standard core material in a laminate floor plank. It is a board, but not a single piece of wood. It is made up of any combination of wood fibers, cellulose fibers, possibly synthetic resins as well and then it is bonded via heat and pressure. Fiberboard usually comes in low density, medium density or high density (LDF, MDF & HDF).

Finish (vs. coating) - A finish is the final layer applied to the top of a floor, one which may be a coating of some sort of liquid, designed to create the wear layer. Coatings could be of a stain, being under the finish layer, or even a wax over it. The ‘finish’ of a laminate floor is a layer of melamine or aluminum oxide, applied more like a sheet of plastic than a layer of goo. That makes a laminate finish something other than a coating, and with a laminate floor you do not want to ever apply some other coating when maintaining it.

Fire Resistance - It’s the ability of any material to withstand contact with fire, or to protect against it.

Fire Retardant - This is a chemical designed to slow or stop the spread of an existing fire over a surface. It may also reduce the flammability of that surface.

Flakeboard - This is a specific type of particle board which is specifically made of flakes rather than just particles.

Floating Floor - Any floor which is not attached to the subfloor is a floating floor. The pieces of flooring might be connected to each other – they usually are, in fact. This type of flooring best handles the expansion and contractions many floors undergo due to environmental changes. Floating installations are part of what enabled some hardwoods to be installed over concrete and in basements. Almost all laminates are floating floors.

Floor ‘covering’ - (see ‘Covering’ above)

Footfall - This refers to the sound, or just the vibrations, caused by walking on a floor, and sometimes to the tendency of the floor to magnify, transmit or hinder the transmission of those.

Formaldehyde - This is the offensive chemical of the day in manufacturing, a volatile organic compound. It’s the primary chemical monitored in flooring plank production, with rating classifications formed in Japan, Europe and for America in California, all of which have affected production. Formaldehyde would primarily be found in the adhesives, both those used in installing the floors and those used in making them. Most laminates today are manufactured using no adhesives, but rather employ heat and pressure to be formed.

Glue - See ‘Adhesive’ above. These are rarely used with laminates, and when done tend to go where tongues and grooves are joined.

Laminate Flooring Glossary of Terms: H-I

Hand-Scraped Style Laminates - You can't really hand scrape a laminate – well you can, but if you do we won't sell it because it will be ruined – so laminate floors have been designed to mimic the hand-scraping done on solid hardwood floors. This is done by texturing the surface, giving it both the wavy feel and some of the tiny bumping and notching. A hardwood floor would be sanded to give it a smooth surface so it would be walkable. With laminates the wear layer already provides the desired smoothness.

Close up of Hand-Scraped texturing.

Heated floors (usually “Radiant Heating”) - Laminate floors are a pretty good choice to go over heated flooring because they conduct heat so well. The things to keep in mind are

1– Your specific floor will have a specific temperature over which your floor surface should not go. Consider that a hard rule.

2 – As with any floor, you will need to conduct a heating test before installing your laminate.

3 – Your padding may need to be made of a high density material, felt or rubber, and a vapor barrier will be needed. Check your instructions for the specifics, always.

4 – If your floor is heated with hot water, you may also need to have a moisture test done before your installation.

High Density Fiberboard (HDF) - The center layer of a laminate floor, the part closest to being the board itself, is usually made of a fiberboard (see above), and these come in low, medium and high densities. HDF is made from wood fibers which are bonded into shape by pressure. Usually no additional materials are needed to do the bonding. The board has a non-porous surface, which makes it ideal for laminates because it can be easily sealed. While it can look the same as a medium density board, its higher density means a higher tensile strength – it's tougher to break. It also does not crack or split, which can happen with particle board. The density is usually around 55 lbs per cubic foot, never less than 31. This also makes the boards less reactive to the environmental changes that affect most plank floors. It resists shrinking and swelling the most of these three.

High Gloss - Not to be a smart aleck, but this just means that the surface of the particular laminate is smooth and really shiny. Like a nice piano. Or glass. That's it!

Hydroscopic - Not just a flooring term but a science term, this refers to the ability of any substance to absorb or lose moisture. Stone is not very hydroscopic, wood is hydroscopic, sponges are extremely hydroscopic. This quality of wood is why it expands and contracts with environmental changes.

High Pressure Laminate - Of two forms of laminate flooring production, this and Direct Pressure (DPL, explained above), HPL forms the more durable floor. Where DPL is constructed using around 400 PSI of pressure, with HPL the layers are bound using 1300 PSI, and in multiple steps rather than DPL's single step. Most HPL laminates receive an AC5 durability rating, the highest rating for laminates, safe for most commercial uses, let alone in the home. This means more resistance to dents and impacts, heat and moisture, general wear and chipping while you install your floor. HPL laminates are more balanced (see above) and tend to be thicker floors than DPL floors.

Impact Resistance - This is specifically about damage, not about the impact itself. It's a marker of how well a thing resists being damaged by a falling object. The only way to resist the impact itself is to use the force, and no one really does that, at least no one famous.

Inflammability classification - There are a few systems used to classify a material's inflammability, the most commonplace being one from Germany designated DIN 4102-B1. Sometimes this will be printed on the labeling, meaning that the product is of low inflammability. There are other systems as well, but laminates don't vary much in this area. They are generally just difficult to ignite, so the designation can be missing in the same way as the note “contains wood” may be left off the packaging because with rare exceptions all of it does.

Rating Degree of flammability Examples A1 100% noncombustible A2 ~98% noncombustible B1 Difficult to ignite B2 Normal combustibility - wood fits in here, laminate is usually one up, at B1 B3 Easily ignited

Inlay - In installation this is a decorative effect where of the same, exact product, but different colors or patterns, are used to make large stylistic features in a floor. Because of the way click together floors are installed, this is almost unheard of in laminates. It's more frequently done with hardwood flooring where the pieces are not connected to each other. We just don't have a lot of that kind of freedom with a laminate floor.

Installation - Basically this is putting the flooring in place. There are three main installation types, all of which come under a general Click Together heading, and most of which are floating floors. See the videos under Click Together above.

Installation direction - It is exactly what it sounds like, but this is an important term to keep in mind. When installing a click together floor, the tongues are always inserted into the grooves. We never insert, or surround, the grooves with the tongues, installing backwards, if you will. This causes all sorts of problems. This means that you will have a direction for your installation. When you start you'll have tongues facing the walls, leaving the grooves available for your next planks or rows. Depending on which sides of the planks those fall on, you will either install left to right, or right to left across your room as you do each row.

Another way to think of this simply has to do with how you want your floor to look, or in which direction you want your rows to be. As a rule you have three options, along one wall, along the perpendicular wall, or at a diagonal through the room. Many prefer to install perpendicular to the traffic flow. In some cases the subfloor may be made of boards, and it may be necessary to install perpendicular to those.

Laminate Flooring Glossary of Terms: J-O

JIS/JAS – The Japanese Formaldehyde Adhesive Emission Standards - Along with the American (CARB) and European rating systems for formaldehyde, the other well used one is the Japanese standard used for any building materials. They measure based on how many micrograms are emitted per square meter of material within an hour. A microgram is a millionth of a gram. Micrograms (μg) per meter squared hour (m2h). μg/m2h. I really had to search to unravel that odd measurement. The ratings basically come down to a star system, 1-4 of them with 1 noting the most emissions and 4 noting the least. Here's how they fall:

F**** – The emission rate for formaldehyde is below 5 μg/m2h. In Japan these materials may be used without restriction. F*** – Formaldehyde emissions fall between 5 and 20 μg/m2h . These are called Type 3 formaldehyde–emitting building materials and have restrictions for use. F** – Here the emissions are above 20 and up to 120 μg/m2h. These are also restricted, called Type 2 formaldehyde–emitting building materials. F* – Materials with this rating have emission rates that exceed 120 μg/m2h. In Japan these materials may not be used in construction. They're Type 1 formaldehyde–emitting building materials, not at all "green".

Joist - Effectively, this is what holds your room up, or a set of them do. Joists are the strongest, most basic building blocks of the floor, big, solid beams, a series of which are laid down parallel to one another beam to support floors or ceilings. On top of these will be laid a subfloor, a series of planks, some large, flat boards or concrete, and atop that the part of the floor you walk on, the floor 'covering' which can be laminate, hardwood, vinyl or what have you.

Laminate - A product made by laying plastic or another protective material over a flat surface. You end up with a flat material, hard or flexible. Technically this would be the top layer of a laminate floor board, but in this industry it also becomes the short way of referring to laminate flooring.

Laminate Flooring - It's a flooring product usually designed to resemble hardwood flooring. The material used to frequently contain plastics and resins, but that is no longer the tendency. The core material is usually made of wood fibers and particles formed into a board through heat and pressure. The top surface is a photographic image protected by a wear layer, usually aluminum oxide. Laminate floors are more durable than hardwoods (you can walk over them in your high heeled shoes, for example) and can be installed in more places than solid. They are also not limited to looking like wood.

They can look like tile, stone, heck they could look like a bunch of Mr. Spocks if someone thought that would sell well enough to produce them.

Laminated Plank Flooring - There are laminate tiles, but 99% of laminate floors are planks, so see above and just add the word 'plank'.

Laminated Wood - Aside from the very general 'Any piece of wood that has been laminated with something' this is also another way some people refer to laminate flooring.

Light Resistance - (see 'colorfastness' above)

Low Gloss - The industry term for this is 'matte', for surfaces that are deliberately not shiny, or glossy.

Here's a very nice low gloss floor, one of our favorite customer photos.

Here's a very nice low gloss floor, one of our favorite customer photos.

Low pressure laminate - These are laminate floors produced by being molded and cured at pressures close to 400 pounds per square inch. High pressure laminates use three times as much pressure in production.

Major Brand - We are a special deals place. Sometimes the conditions of our selling something at such a low price is that we are not allowed to cite the brand name on our website – they're still trying to sell it on theirs at full price, you see. So we call it a "Major Brand". How can you crack this code? Easy. Just search online for the name of the product, for example "Iron Mountain Vinyl Plank Flooring," and include the last 4 or 5 digits of our SKU code from that product's own page. So in my example you would add "66179" into the search box. We keep that part of their code because it's on the cartons, and it helps us make sure to get the right stuff out our doors to you. If you search for those, the same products should come up with their official brand names (and prices) from other dealers and the manufacturers.

Manufacturing Defects - These are defects or blemishes that don't come from a transportation mishap or misuse of an installed floor, but tie directly back to the manufacturing process. With a laminate floor they will be major things like banana boards (listed above) or uninstallable planks due to mis-manufactured locking mechanisms. Other issues would be the kinds that can appear on some planks in a second quality laminate floor, illustrated in the linked video.

Matte Finish - see 'Low Gloss' above, though in reality this is the proper term for it.

Medium Density Fiberboard (MDF) - This is similar to High Density Fiberboard but made with less pressure and in some cases softer fibers. Typically the density falls between 500 and 1000 kg/m3, or 31 to 61 lbs/ft3.

Melamine Resin - It's a hard plastic, a thermosetting material used in kitchen utensils and plates, the ones that aren't microwave safe. When resins are used in the production of laminate flooring, this is usually the one employed.

Modern Style Laminates - What this means is 'whatever is trending', so we can't lay out a specific set of styles and features. When you shop for laminate flooring, this is the category where you will find the newly popular.

Moisture Barrier - This is used atop the subfloor, under the laminate flooring, where moisture buildup would be an issue, say over concrete. These come in nice, large rolls. If your laminate comes with attached padding, any moisture barrier needs would not be met because there would be a gap where the planks meet. On the other hand, almost all padding intended for laminates automatically comes with the moisture barrier component.

Moisture Content - It's the amount of water in any material. It is usually given as a percentage, specifically of the dry weight of the material. With flooring we aren't usually concerned with the content of the laminate so much as that of the subfloor.

Moisture Meter - A professional, usually expensive tool used to very specifically measure moisture content. If you hear your installers talking about pin type or pinless meters, or the Tramex Moisture Encounter or a calcium chloride test, this is what they're talking about.

Moisture Resistance - This is different from water resistance. A water resistant floor is going to keep sitting water from absorbing into the material. Moisture resistant material is also going to resist soaking in humidity, the moisture in the air.

MSRP - This is the Manufacturer's Suggested Retail Price. That's the technical definition. Colloquially it means "Never, never, never pay more than this amount, and even this is probably too high."

Off-Goods - This does not mean or in any way connect with 'knock off goods'. To be honest, I thought this was just one of our little words, but I found that at least one of our manufacturers uses it too. With us it means anything we buy as a close-out, a factory second, an overrun in production, a discontinued item or other similar things, products you would expect to find at an outlet store. With Armstrong floors it means any material they produce that does not meet their specific 1st Quality grade standard for that particular product. These can be things that would be a defect in any floor, or things that don't happen to meet a particular product's desired look.

Overlay - With laminate flooring this is the top layer of the finished plank, a coating that goes over the image itself. It's also called the wear layer, and it's job is to keep your floor from wearing out as you walk and live on it

Laminate Flooring Glossary of Terms: P-R

"Padding being installed"

"Padding being installed"

Pad – Floor pad is usually required under a floating laminate floor. If you think about it, with laminate you would be putting a hard, flat plank on top of a hard, flat subfloor. The padding eliminates clacking and helps these two surfaces handle micro-milimeter sized imperfections that any floor can have. We have written some pieces on Padding in general (with video!), When You Need Floor Padding and How Much ‘Stuff' Can Be Under Your Laminate Flooring that should be really helpful in helping you determine what you need and want.

Pad Attached - Many laminate floors come with padding pre-attached to the bottoms of the planks. This can make installation a little easier or just eliminate the need to buy the rolls. The padding is almost always 2mm thick, which is the standard, basic thickness of a laminate floor padding. With certain thicknesses of laminate more is allowed underneath, so that if you do buy rolls the two in combination can lead to a softer walk. Be sure to check the piece linked above on how much can go under a laminate.

Pad, Free (usually shown as "Free Pad!") – We offer this with most of our laminate floors. It means that either the laminate has attached padding, or that we send the needed amount of basic padding along with the floor order. It just makes padding one less thing to think about and manage as you buy and/or install your laminate floor.

Pad Included - we send it with your order!

Pad Included - When we note this, it means that the padding is not attached to the planks, but that we include it with your purchase.

Pad Not Included - This means that free padding is not offered with the particular laminate floor.

Panels - Finished pieces of laminate flooring. These can be planks or tiles (usually squares). The more common term you'll hear is plank because most laminates come that way. You'll hear that even over ‘board', because technically a board is made from a single piece of wood (see ‘board' above, where I say the exact same thing… so I guess you could just stay here).

Particleboard - This is a board made not of a single piece of wood cut into shape, but also not made of multiple layers, like a laminate plank. It's made of little bits and pieces, all bigger than fibers, bonded together into the shape of a board with heat, pressure and sometimes a synthetic resin. These can be used as core boards in some products, but are usually not what we find in laminates. Those tend to be fiberboards.

Pattern End Matched - You probably won't hear this one much. It describes the ends of different flooring panels being designed so that where the planks meet at the ends the pattern continues unbroken. It would give the effect of multiple planks connected together looking like one really long board. The only product we have carried that employs this feature is our Krono Original Double Length Laminate Floors, designed to be installed with the planks paired together to look exactly like double length boards in the finished floor.

The matched ends allow the planks patterns to flow together.

Moisture Barrier made of plastic

PE Film (Polyethylene film) - This can be the substance of a moisture barrier, or what you may hear called a vapor barrier, two different terms for... well, for two different things. With flooring we need a moisture barrier, not a vapor barrier. These will usually be 6 mils thick (about 1/7 of a millimeter), and go between a cement subfloor and the padding under your laminate. It is designed to keep moisture and humidity from rising up from under the flooring.

Peaking - This happens when moisture is absorbed into the core board of a laminate plank. This area swells, deforming the plank and sometimes raising one plank above the other where they join at a seam. This kind of damage is irreparable.

Peaking shown where the two planks join and on the end closest to the camera.

Peaking shown where the two planks join and on the end closest to the camera.

Performance classification – This is obviously a generic term, but in flooring it refers to the European system of designating the uses for which a laminate plank is qualified. It covers some of the same territory as the Abrasion Class rating. The designations cover moderate, general and heavy usage for domestic purposes and the same three levels for commercial purposes. The tests cover a laminate's resistance to abrasion, cigarette burns, damage from furniture legs and chair castor chairs, impacts, staining and swelling. Here's what the symbols on the cartons will look like:

Plank - Technically is a tile which happens to be at least five or six times wider than it is thick, five or six times longer than it is wide. It is also the term used for most individual pieces of laminate flooring, rather than ‘board'.

Plank Design - On our site this refers to whether each plank is designed to look like a single plank, like two vertical planks, three, a whole bunch of little ones or a tile look.

Pollutants - With a laminate floor the pollutants that concern us would be in any solvents, such as the formaldehyde which can be in resins used in manufacturing the planks. At the present (we're writing this in 2014) laminates in general are so low in pollutants that laminate flooring is widely regarded as ‘low-emission' or ‘emission-free', meeting the CARB standards and earning it the E1 rating in Europe.

Pressing - This is the part of the laminate manufacturing process by which the different layers are combined using pressure. When would you hear this? Perhaps if someone might say "That defect must have happened during pressing," otherwise it is not likely to come up in many conversations about laminate flooring.

Pressure resistance - This would broadly cover the impact, high heel and furniture dent resistances of a laminate floor, but they are usually broken out like that rather than being referred to this way. As a rule, unlike real wood, which is all to some degree ‘spongey', or able to be compressed, most laminates are not. They either do nothing or they chip or break, and fortunately the resistances are stronger than those of wood, so this does not render them fragile. For instance there is at present no hardwood floor over which we would recommend walking in high heels, while almost all laminates can handle that.

Quarter Round

|

Quarter Round - It's a pretty common trim piece, and we explain it in detail, with some passable illustrations, in our Quarter Rounds piece in the Learning Center. Reducer Strip - Another trim or transition, this one used where two floors meet at different heights. See illustrations and explanations on the Reducer page in our Learning Center. |

Reducer

|

Relative Humidity - This is how much water vapor the air is holding compared with the amount it could hold. Some densities and temperatures of air can hold more water and some less, but all have a limit. This is a percentage based not on some stable number, but on the particular limit of the particular bit of air. When relative humidity reaches 100% we can get rain and moisture stops evaporating. The air there can't hold it.

Residential Warranty - For flooring, designations are made on where they can be used, in a residential situation or a commercial one. This affects things like ratings and warranties. A floor may have this listed, "25 year Residential/5 Year Commercial Warranty". If that flooring is installed in a commercial location, where traffic and wear are expected to be high, it has a 5 year warranty. If it is installed in a home the warranty lasts 25 years. For more on warranties in general, we have some articles that start here, What is a Warranty?, with specific ones linked at the bottom.

Residual Indentation - One of the tests performed in getting the AC Rating (see above) is called the Static Load Test, which basically means that something heavy is left in place just as your furniture leg might be on your floor at home. Residual indentation is what is, or is not, left behind after the heavy thing is moved. Most laminates don't indent at all. Their surfaces are usually rigid, not pliable.

Resins - The word is often used to broadly describe any liquid that sets into a hard, transparent surface or finish. This can include synthetic substances that do this, but more technically refers to naturally produced chemicals with these properties. In flooring it is most often found in adhesives, usually not used with laminate floors, and with laminates it used to be used in their production, but it not as much, with pressure and heat taking their place in bonding the materials resins used to keep together.

Laminate Flooring Glossary of Terms: S

Scratch Resistant - This refers to the fact that, or how much, a laminate is able to not be scratched by scratchy things. Most laminates will list this term as a quality, meaning that the laminate does this. There is not a rating for how scratch resistant a laminate floor is.

Seam - Anywhere two planks connect together, that's a seam, whether beveled and obvious or glossy, smooth and flat.

Second Quality - This is similar to 'off goods' above, sometimes a synonym. When a factory produces a laminate floor, they have sets of specifications the final product must meet, and if a certain plank doesn't, but is still installable, it becomes a 'second'. We have a video located in our article, What are Laminate Flooring Seconds, and How Do I Get a Great Floor? which we filmed at a house where these were being installed. We show the planks and the process we used to get the finished floor to look like this at about ¼ the normal price for this flooring.

Shoe Base – see Base Shoe. Same thing, it just depends on who's speaking. Po-tay-toe, po-tah-toe.

Skirting board - see baseboard. For the explanation see Shoe Base.

Single Plank - This is a style of laminate flooring where each plank is designed to look like a single board, vs. styles where a plank of laminate may look like it has two or more boards already together in the long direction. We have pictures of these different styles under Plank Design above.

SKU – Are you ready? "Storage Keeping Unit"! That's what that means. SKU stands for storage keeping unit. It is any individual place or business's code for any particular thing, separate from the thing's own code, such as a UPC code or a manufacturer's code. It is often pronounced 'skew', though I prefer the rarely used 'skoo' myself. Ess-kay-yoo is the way our customer service people should say it to you since it's such an insider term, but you can say any of these to us and we should know what you mean.

Smooth Surface - This means that the surface is not textured. There is no distressing or hand-scraping texture to these. They can be high gloss or matte, any level of shine.

Species (with laminates) - The species designation is usually used for hardwood, where a particular species of tree is made into the boards. There are not actual species of laminates, but since they can look like hardwood, the designation can tell you what type of wood was used for the image. This way if you're looking at a product called Winter's Bone, you can see that it is a stylized pine, for instance.

SQFT - The abbreviation for Square Feet. That's the measurement by which most flooring is sold. It comes from taking the measurements of the length and the width of your floor area and multiplying them. A 10' x 10' room has 100 sqft of flooring. If you have a 12' x 16' room you have 192 sqft. 1' x 1'? You'd have one square foot of flooring. One. Who has a room like that? No one. That's called a clothes hamper.

Square Edge - This is one of the two main types of designs for the edges of your planks, in which they link together snugly and smoothly, forming an undisturbed flat surface across the seam. With the other, 'beveled', an angle is cut so that as planks meet they form a V shaped notch, emphasizing the outlines of each plank.

Stabilizing layer – This is the bottom of a laminate plank, a structural, hard layer that attaches to the bottom of the core board and gives it extra strength. In combination with the top layers it balances, or stabilizes, the plank.

Stain Resistance - This is a nice one, because aside from just water, the biggest non-violent issue with a floor is the spilling of something like wine or, you know, blood. Most floors are going to stain, older carpets especially, some vinyls, many woods depending on the finish used – but laminate handles these things quite well. The standard surface coating is so non-porous that the staining molecules don't really get a hold. One common test, and you'll see it in some of our videos, is the Sharpie Test, where we mark on a laminate with a Sharpie Permanent marker, then wipe it right off with acetone. Take a look at this video starting at 53 seconds in.

Strip Flooring - With laminates this refers to styles designed to look like multiple planks, lengthwise, two or more, but more specifically may refer to multi-strip flooring, where the look is of many strips an inch or smaller in width. See an example above under Plank Design.

Substrate - This is the technical name for the core material of a laminate floor plank.

subfloor - This is the top structural support layer of a floor's foundation, over which a finished floor is laid. Generally these are made of wood or concrete, and the condition of your subfloor must always be checked and attended to before installing any floor covering (laminates, hardwood, vinyl planks etc.)

Surface Layer - This is a broad term for the top layer of a laminate, hardwood, what have you – the part your foot touches and that you see day to day.

Laminate Flooring Glossary of Terms: T

Taber-test – This is one of the AC Ratings test, covering abrasions. The machine rotates a test piece of the laminate under an abrasive source, and the number of contacts needed to get the surface to show wear determines the classification for this test.

Tap n Go - This is an older style of laminate floor installation, shown below. Basically each plank of laminate must be tapped in (with a mallet, so it's a bit more than a 'tap', but not quite hammering) to secure the connection between the planks. These are much less popular than they used to be, but there are still some being made.

Textured Surface - The opposite of a smooth surface, this will refer to the surface of any laminate which has been given a distressed look, hand-scraped look, or has any other kind of physical feature on the top. These can be high gloss or matte, and are likely not the sorts of floors over which one wants to slide in the socks.

Thermofusing - It has to do with resins, which used to have a lot to do with laminates. Heat and pressure are used to bond them into the needed substance.

Thermosetting Resins - These are heat safe materials, if not always microwave safe. They cure (see above!) via a chemical reaction, so that heat does not undo the chemical bonds as it might with a heat cured substance.

Three Strip - This is one of the main styles of wood look laminates, in which a single laminate plank is designed to look like three narrow rows of wood.

Thickness - With laminates the range of thicknesses is currently between 7mm and 12.2mm. You'll see some listed at 14.2mm, but those are counting an attached, 2mm pad. The range seems slight, just under 1/5 of an inch, but it's often the first factor on which people decide when looking at the technical specifications. A thinner laminate might be less durable (though not necessarily, as some of our toughest floors are 8mm Kronoswiss laminates).

Tile - In flooring it's a piece that is not significantly longer than it is wide, those being planks. These are usually squares but they can be rectangular. Tile could also refer to the very small pieces of wood used in making a parquet wood flooring.

Tile Look - Laminates with a "tile look" are meant specifically to look like ceramic or stone tiles. See an example above under Plank Design.

Tongue and Groove - This is a type of laminate installation which slightly differs from click together. The planks are connected to each other, and form a floating floor, but they do not click together with a locking mechanism so much as the 'tongue' end of one juts out and fits into the 'groove' cut into the end of another. Click together floors have mostly taken these over in laminates.

Traditional Style Laminates - This is our technical way of saying, "Looks like hardwood flooring". The first laminates were made to look like real wood while solving some of the issues brought by using such natural material, mainly how it responds to the environment. This category would exclude newer styles like the stone tile looks, or unique colors like greens, blues, deeper reds - even black laminates would likely be grouped as modern rather than traditional.

Transitions - Transition pieces get lumped in with trims, but the distinction is that a trim goes at the edge of a floor where it meet a wall or something else vertical. Transitions are designed to go through a walkway in between two sections of flooring. These would include things like t-molds, which go between floors of the same height, and reducers, which cover the gaps between floors of different heights.

Trims - Broadly this refers to both trims and transitions, but more specifically a trim is a narrow piece of wood cut to fit at the edge of a floor, usually where it meets the walls or any insets into the room.

Two Strip - In this style of wood style laminates, a single laminate plank is designed to look like two rows of wood.

Laminate Flooring Glossary of Terms: U-Z

(really 'W', there are no Xs through Zs)

Underlayment - See pad above, but basically this is anything designed to be lain under the laminate floor, a cushioning between it and the subfloor.

Unidirectional Bonding Strip – What Buzz Lightyear calls Scotch tape. This rarely comes up with laminate flooring.

V-Joint - See 'Beveled' above. We would use this as a description of what happens with beveling, but for some it's the term.

Vapor Barrier - Similar to Moisture Barrier above, and some think they're interchangeable, but they really aren't. A vapor barrier is for the walls, a part of a 'house wrap', and it's designed to breathe a little. For flooring we're looking for moisture barriers.

Wainscotting - This exceeds the description of a floor trim, though it may function as a baseboard, if a really, really tall one. This is usually going to be some kind of wood paneling that lines the lower part of the room. It's not just a few inches but usually more than a foot or two in height, capped with some kind of molding, sometimes even chair railing.

"Very stylized wainscotting decorates the lower few feet of these walls."

Wall clearance - This is almost just another way to refer to an Expansion Gap (see above), in that the same number will describe the measurement. It's the distance between the wall and the outer edge of your laminate floor. I suppose one could use both in a sentence, say, "You need at least 1/4'' of wall clearance for your expansion gap." But honestly, that's almost a tautology.

Warp - A detrimental, physical distortion. With laminates it would take the form of crowning, cupping or crooking, all of which are listed above. This will usually occur when a floor has been installed without enough space to expand (or worse – without any). The planks, having nowhere to slowly slide, push against each other and distort.

Waste Material - When you install a floor you will need to cut some boards to fit onto the ends of rows, or to go around corners, fireplaces, or any number of things. Boards cut from the ends of rows can usually be used at the starts of other rows, but there will still be some leftover pieces. Also, accidents happen – you may just lose a board or two. With any first quality floor we usually recommend adding 10% to your square footage purchased, and with any seconds we recommend 20%. This is pretty important because of the shipping. If you buy too much flooring because of these percentages, you may have some spare planks left over, and that can be handy if there is future damage. If you buy too little and need, say, one box? Sometimes the shipping is more expansive than the box. I'm not even close to kidding.

Waterproof - We have a full article on Four Important Waterproof Flooring Terms that covers this in detail. So far there is no such thing as a waterproof laminate floor, but if a plank of vinyl flooring is 100% waterproof, then water is not going to damage that plank. If a bunch of waterproof planks are on a floor, then a flood in that room is not going to hurt those planks. This does not mean that the planks are going to keep the flood from hurting the structure underneath them. It's a flood - they just do what they do. The planks are waterproof, they do not waterproof the house. The benefit is that after you clean up the flood just as you would anytime it happens, you don't need to buy a new floor – the waterproof one just goes right back down.

Water Resistant - Laminates can be called water resistant. Now, this does not mean that they are waterproof. It means that they are designed to keep water up on the surface of the floor as a whole. The top of an individual plank is basically impermeable, so the Achilles heel for laminate is the seams. If water gets between those it can soak into the core board. Water Resistant laminates do their best to keep water out of the seams, either through the design of the locking mechanisms, using wax at the seams or having a special chemical in place that repels liquid, like the Click Guard we get to send with certain products.

Wear Layer - It's the top layer of the laminate plank, the part you'll directly contact when walking. It's called the wear layer because it's designed to not wear, to resist abrasion. It includes the clear, protective, top covering layers as well as what you see as the image layer, because even that is engineered to resist wear.

Wear Resistance - This is the degree to which the wear layer is able to prevent wear from happening through to the decorative layer.

– – – –

David has written and made videos about flooring products and installation since 2011 at Floors To Your Home (.com), where he is also the PPC Manager, a Researcher, a Website & Marketing Strategy Team member, Videographer, Social Strategist, Photographer and all around Resource Jito. In my spare time I shoot and edit video, put together a podcast, explore film history, and mix music (as in ‘play with Beatles multi-tracks’). Connect with

W. David Lichty

Follow Team Floors To Your Home on Facebook

Brown Tone

Brown Tone

Unfinished

Unfinished

Red Tone

Red Tone

Golden Tone

Golden Tone

Gray Tone

Gray Tone

Light Tone

Light Tone

Medium Tone

Medium Tone

Dark Tone

Dark Tone

Brown Tone

Brown Tone

Red Tone

Red Tone

Golden Tone

Golden Tone

Gray Tone

Gray Tone

Light Tone

Light Tone

Medium Tone

Medium Tone

Dark Tone

Dark Tone

Brown Tone

Brown Tone

Red Tone

Red Tone

Golden Tone

Golden Tone

Gray Tone

Gray Tone

Light Tone

Light Tone

Medium Tone

Medium Tone

Dark Tone

Dark Tone

Multi Color

Multi Color